We have versatile filling lines that allow us to fill fluid, semi-fluid and emulsion products and/or gels even at high viscosities.

We regularly carry out metrological weight control (verification of the filling level according to current regulations, performed by checking the weight of a number of samples calculated on the total number of pieces making up the batch).

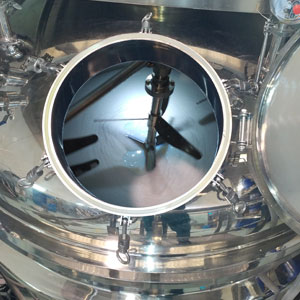

All machines are regularly washed and sanitised at each product change, in order to complete the cycle of pollution prevention begun during the production phases and thus guarantee the microbiological purity of the finished product.

We have 1 6-flame and 3 2-flame phial filling machines with a production capacity of 70,000 phials per day in various diameters and capacities from a minimum of 5 ml to a maximum of 25 ml.

With regard to single-dose or small-capacity bottles, we are able to produce small batches with carousel fillers and large quantities with automatic in-line filling machines with pressure, screw and crimp closures.

The fleet of machines for filling bottles and jars consists of machines suitable for all types of products in the various technical shapes and containers.

We have semi-automatic filling heads for small batches and automatic in-line filling machines with ink jet and double labelling heads for high volume production. Fillable capacities range from 30 ml to 10 litres.

Any type of plastic tube can be made by us with an automatic air tube-filling machine for large productions and a carousel hot-grip tube-filling machine for pilot or medium-small batches.

Heat-sealed soft bladders made of aluminium or plastic materials are also part of the type of containers we fill.